Graduate student Jason Kerestes wears his 4MM jetpack on the Tempe campus on Sept. 17. ?(Photo by Emily Johnson)

Graduate student Jason Kerestes wears his 4MM jetpack on the Tempe campus on Sept. 17. ?(Photo by Emily Johnson)ASU engineering graduate student Jason Kerestes has developed a one-of-a-kind jetpack that enables users to run a four-minute mile, and the invention could have a bight future in extreme sports as well as potential military applications.

Kerestes, who studies on ASU’s Polytechnic campus, said working on the 4-Minute Mile jetpack has so far been a fun and rewarding experience, but the project was not without its challenges.

“The human body is engineered amazingly well,” Kerestes said. “It’s capable of so many things. Your muscles are capable of perfect timing and so forth. It’s really difficult to make someone better than they already are, and so that was really the biggest challenge of this project — finding a way to make the human body better.”

The project was initially inspired by earlier work at ASU on a robotic ankle for disabled veterans, he said. But as work on the ankle progressed, the question arose of how robotics could benefit soldiers who were not disabled as well.

Kerestes said the military posed an interesting question three years ago: “If you can do this for disabled people, what can you do for able-bodied people?”

He then set to work with ASU engineering professor Thomas Sugar to begin a project initially funded by the U.S. military, in order to build machines that would enhance the physical capabilities of soldiers.

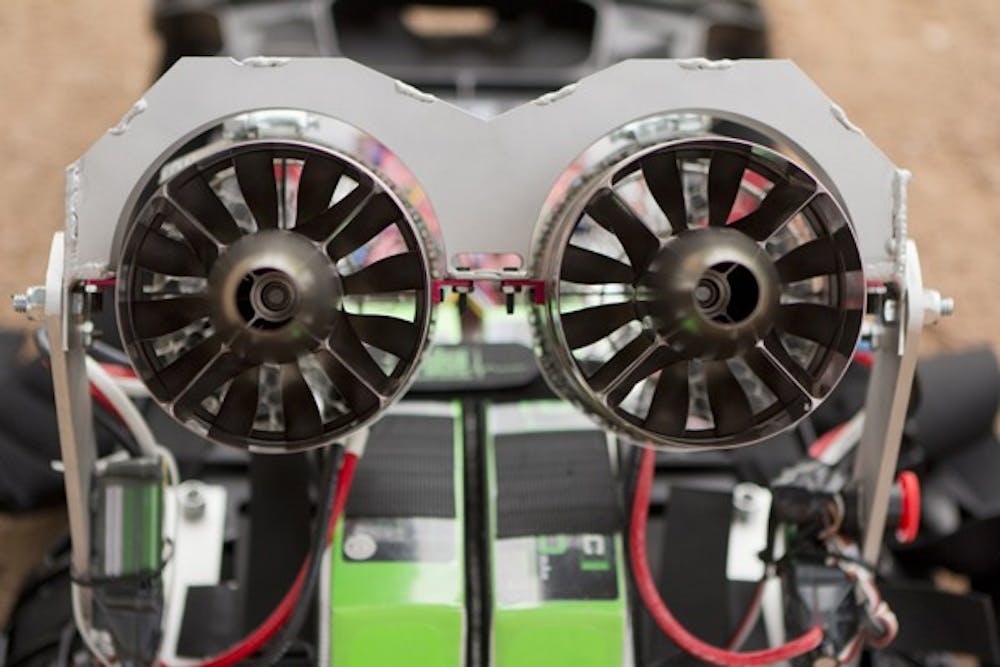

They have since developed two devices: AirLegs, a type of robotic exoskeleton that assists faster adduction and abduction of leg muscles by creating torque around the joints, and the 4MM jetpack, which uses electric ducted fans like those found on some remote control helicopters to propel users forward.

Both devices help to increase runners’ speed and decrease their metabolic cost, but Sugar said the 4MM jetpack has certain advantages over wearable robots such as AirLegs.

“Most, if not all, wearable robots actually make it harder for the person to walk or run because the robots impede gait ever so slightly and must overcome the weight burden,” Sugar said in an email.

The 4MM jetpack designed by graduate student Jason Kerestes could possibly help soldiers and athletes.? (photo by Emily Johnson)

The 4MM jetpack designed by graduate student Jason Kerestes could possibly help soldiers and athletes.? (photo by Emily Johnson)The 4MM jetpack faces no such problem.

ASU multimedia technician Alex Chapin produced a four-minute documentary video on the pack in June, and it now has over one million views on Vimeo.

Chapin was both behind and in front of the camera during the filming process, however, as he can be seen testing the pack at the video’s 3-minute mark.

“It’s kind of like on a windy day, when you have the wind at your back,” Chapin said of using the jetpack. “It has that kind of push, and it makes it easy to run.”

Kerestes said it was easy to imagine his jetpack benefitting soldiers in combat, but he has also “unofficially” tested it on a long board and said he enjoyed the experience, suggesting pack might have a future in extreme sports as well.

The long boarding adventure considered, however, Kerestes said one of the greatest aspects of this project is being able to learn and work on the Polytechnic campus, where he said “everything any inventor or designer could ever want” is at his fingertips.

“I came from a welding background,” he said. “I owned a welding company, but I never had access to all the equipment that I do here. What’s so amazing and unique about our lab — and also the most fun part for me — is that I can design something on a computer, and I can go literally the same day to our machine shop and fabricate it.”

Reach the reporter at megann.phillips@asu.edu or follow her of Twitter @megannphillips