Fashion and technology collaborations are happening more often as modern technology helps spark innovative new ideas for many designers within the billion dollar fashion industry.

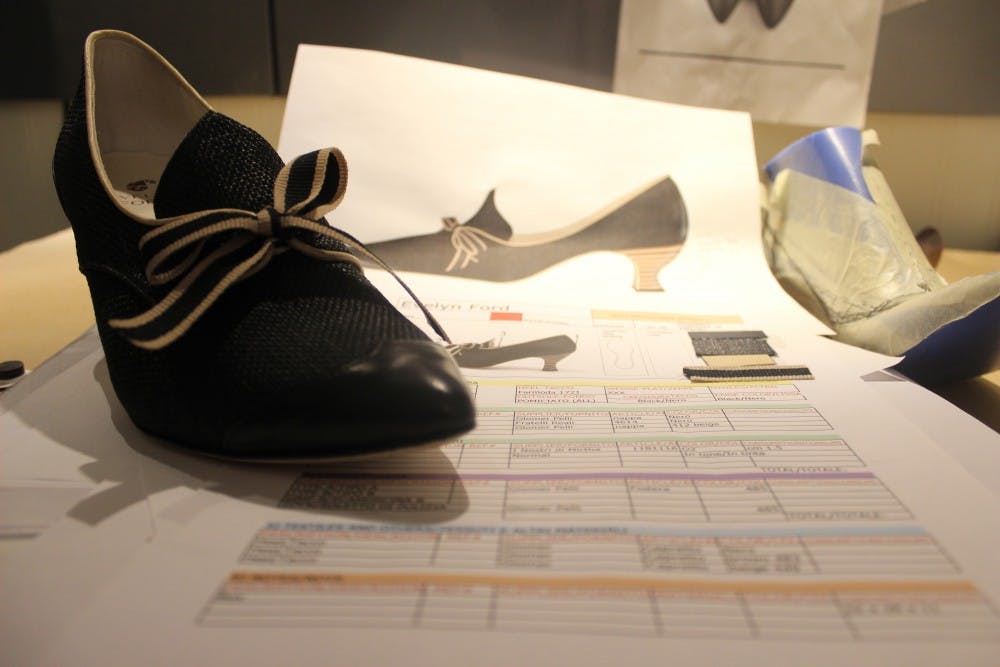

For Evelyn Schickling, a local business owner, founder and shoe designer for Evelyn Ford Luxury, technology plays an essential role in making fashionable shoes comfortable – specifically, her line of fashionable, luxurious shoes handcrafted in Italy.

With history working as a financial manager, Schickling says the dress code consisted of “painful pumps or heels,” and choosing between comfortable or fashionable. Additionally, during her time working there, Schickling underwent four foot surgeries that also led her to wear “clumpy, thick-soled” sneakers to work — which required her to get a special dress code permission.

With these experiences in mind, Schickling decided to attend Arsutoria School, a footwear and bag making school in Milan, Italy, to learn to create a fashionable and comfortable shoe.

“I love solving big problems like this,” Schickling says. “This is really fun to think of all the women that are going to be able to wear comfortable, pretty shoes and not be relegated to flat, sneaker-like things.”

After learning about shoemaking, Schickling began working on her goal for comfort with a small arch support insert prototype. After doing so, Schickling says she realized she needed engineering help.

After about a year-long process of working on the prototype, Schickling reached out to ASU and applied to implement her business project into the capstone program at the Ira A. Fulton Schools of Engineering.

It was then that she decided to give students a chance to incorporate their problem-solving engineering skills to further improve her original design.

“I met with (the students) a little bit more in the beginning to show them the shoemaking process and working on the customization of the arch support,” Schickling says. “We had to evaluate and get the baseline for the project, and they had to understand how the foot mechanics work.”

It was during this first iteration of the project in 2017 that Schickling’s team of students led to a breakthrough: a new way of inserting her prototype and working toward a comfortable shoe.

After a factory mistake involving the misalignment of the snaps, one student in the team suggested using neodymium magnets, which are much stronger than the ones found at a local hardware store. A part of the course goal was met: to figure out a better, more convenient and reliable way to insert the arch support into the shoe.

“It was really hard to get from my little prototype to the finished prototype,” Schickling says. “This is such a wonderful collaboration on so many levels. I really like giving the students a chance to work with these because it’s something different, something outside of the normal thing.”

From her experience in merging the two fields, Schickling also says she hopes to see the same collaborations happen within the two programs at ASU.

“I’m really excited to think about a collaboration between the fashion department at ASU and the technology department. That I would love to see happen in a big way,” Schickling says. “I’d love to be a part of making that a reality for the students because I think there’s a huge potential with some of the technologies we have available now.”

Micah Lande, assistant professor at the Polytechnic campus and former mentor of the student group, says this collaboration consisted of not only finding a better arch support attachment and 3D printing, but also gait testing and analysis.

The gait analysis, Lande says, was “to understand the forces at work, putting somebody walking on a treadmill in a controlled environment where you could measure those forces to … try to quantify what it may mean to be comfortable or more comfortable.”

Lande says the material testing demonstrated that the 3D-printed material is more robust than the traditional material created from a mold. Students concluded that the 3D-printed arch support provides more reliable comfort as well, Lande says.

“It provides confidence that this is something that works and something that can be scaled up to a production market,” Lande says.

Furthermore, Lande says this project exposed the students to hands-on work outside of the traditional engineering problems. During the two-semester-long capstone class, Lande mentored the group of students, who brought in mechanical, electrical and advanced manufacturing engineering skills.

“Our student team took some of the ideas and worked closely with Evelyn to advance them,” Lande says.

After the first year, Lande says Schickling decided to remain involved with the engineering students at ASU. This year, it is a new group of students working on the “next set of engineering problems” of the shoe. Although it is a new work in progress, and not much information can be given away yet, Lande says the goal is still to look at how to extend and improve the design for a good, comfortable fit as an extension of the first iteration of the project.

Recent ASU engineering graduate from the first group, Joseph Haro, says his particular task was to help with the 3D printing as well as collaborate with the engineers Schickling previously worked with. Haro also contributed to in the reliability testing.

He says it was interesting to see how Schickling was merging fashion and technology, motivating him to pursue the project.

“It allows us to branch out to other fields such as fashion, other genres, other disciplines,” Haro says. “There is a whole population of people out there that are interested in other things such as fashion, so we are able to show those people how technology and fashion can kind of merge to create a product that is beneficial to them.”

Schickling hopes to continue improving the comfort in a pretty shoe. After four years of working as a shoe artist, Schickling says her first big production will officially launch this March. Her arch support insert, she says, has a patent pending, but she hopes to license it so that other designers could incorporate the same comfort into their lines.

“Shoes are so important because you’re standing on them,” Schickling says. “You’re using them every day. We live in a culture where we wear shoes, and if they’re not comfortable, it’s misery.

“And I think objects should be beautiful,” Schickling added, saying she is inspired by the Italians’ special care and attention to detail, which she observed in Milan. “I just want to make beautiful shoes that people are happy wearing.”

Reach the reporter at tespana@asu.edu or follow @thaliamespana on Twitter.

Like The State Press on Facebook and follow @statepress on Twitter.